Tasman Sparkies has extensive experience working with businesses, property managers, builders, and contractors throughout Nelson & Tasman. We understand commercial electrical demands—large loads, complex systems, tight timelines. From the outset, we commit to safety, quality, and compliance so your project is delivered on budget, on time, and to specification.

Commercial Electrical Services and Test-Tagging

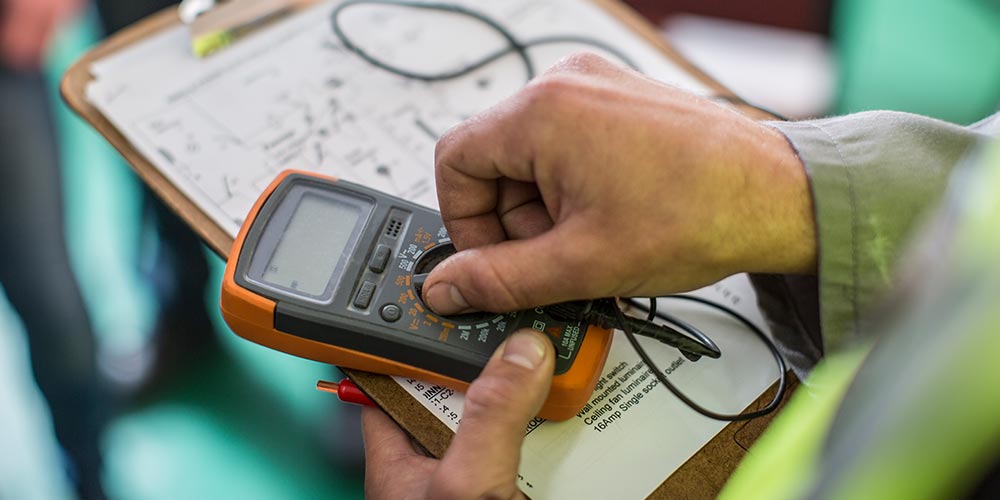

From retail fit-outs to industrial sites, Tasman Sparkies provides commercial electrical services and certified Test & Tagging to keep your business safe, compliant, and running smoothly.

Why Us?

Trusted Electrical Partner for Commercial Projects

Proven Commercial Experience

We’ve worked across offices, retail, warehouses, and industrial sites, delivering reliable electrical solutions for businesses of all sizes.

On-Time, On-Budget Delivery

Commercial projects run to tight schedules. We coordinate with builders, project managers, and other trades to ensure deadlines are met without costly overruns.

Compliance You Can Trust

From AS/NZS wiring rules to Health & Safety requirements, we ensure every installation and upgrade is fully compliant and documented for peace of mind.

Minimising Disruption

We plan and stage work to reduce downtime, allowing your business to keep running while we handle the electrical upgrades.

Safety Standards

As Hazardco members with a strong safety record, we uphold best practices on every site to protect your staff, customers, and assets.

Our Services

Powering Commercial Projects Across Nelson & Tasman

We provide a full range of commercial electrical services, delivered with careful planning, high-quality materials, and strict compliance with New Zealand codes and safety standards.

Full Fit-Outs & New Commercial Builds

Complete electrical design & installation for new commercial spaces: shops, offices, warehouses, showrooms. Includes power layouts, lighting, data / comms cabling, and switchboard capacity.

Lighting & Emergency Lighting Systems

Interior and exterior lighting, feature lighting, energy-efficient LED upgrades, exit & emergency lighting to comply with NZ Building Code requirements.

Switchboard & Power Management Upgrades

Modern lighting design (LEDs, feature, ambient, task lighting), moving or adding light fixtures, kitchen and wet-area lighting, decorative lighting upgrades.

Data, Communications & Automation

Structured cabling, network / fibre readiness, automation of lighting/security/HVAC, integrating technology for modern business demands.

Maintenance, Repairs & Emergency Services

Regular scheduled maintenance to prevent failures, fast response-time for faults, repair services, and backup systems to reduce downtime.

Specialised / Industrial Systems

HVAC electrical work, control circuitry, large motors, industrial lighting, backup power, fire alarm / security system electrical work.

Process & What to Expect

Working Seamlessly With Builders

We follow a clear, structured process designed to fit smoothly into your build schedule. From early planning through to installation and final certification, our team ensures every stage is completed efficiently, safely, and to specification.

1. Consultation & Site Survey

We assess your commercial space, review design or fit-out plans, discuss power demands, lighting levels, safety requirements, and coordinate with other trades and stakeholders.

2. Quotation & Planning

You receive a detailed quote covering materials, labour, scheduling, regulatory needs, and any special provisions (e.g. emergency lighting, compliance). We lay out a plan that works with your construction or refurbishment timeline.

3. Installation & Integration

Our team conducts installations of wiring, lighting, power systems, data cabling, and switchboard upgrades, working with other contractors and maintaining safety protocols & clean workspaces.

4. Testing, Certification & Safety Checks

All systems are tested according to NZ standards; emergency & exit lighting is tested; switchboards are labelled; everything is signed off. We ensure documentation is in place for code compliance.

5. Ongoing Support & Maintenance

Once operational, we provide maintenance plans, periodic inspections, and fast-response repair services so your electrical systems continue running safely and reliably.

Electrical Testing & Tagging

What is Test & Tagging?

Testing & Tagging is the process of inspecting and electrically testing portable and fixed appliances, then tagging them for safety. It provides a snapshot of safety at a moment in time under the standard AS/NZS 3760.

Why It Matters for Your Business

Test & Tag Frequency Guidelines

Environments like construction sites, workshops, or outdoor use: every 3-6 months.

Offices, retail spaces, less exposed environments: every 12 months or as per risk assessment.

Full inspection & testing of appliances, leads, tools, power boards etc.

Tagging with details: safety status, next test date, who tested.

Advice on test intervals according to environment (office, workshop, wet/damp, construction site).

Authorised registered electricians to rectify any issues found.